HOME | 1 | 2 | |

|||||

Pontoon Trailer Bunks and Coverings |

|||||

| Most pontoon trailers have 2” x 4” wooden bunks. They are usually lag bolted from beneath, through the bunk brackets into the wood. Most companies use full length bunks. One single piece of wood but some companies use only 8’ bunks, sometimes butted together or sometimes separated. | |||||

|

|||||

|

There is no benefit to the

retail customer of not

having a full length bunk,

but it makes it easier for

the manufacturer and

distributors to handle 8’

bunk rather than 16’ or 20’

bunks. There can be a

potential of danger with

individual bunks. On a

launching ramp with a steep

angle the pontoon boat nose

cone could potentially get

wedged in the space not

covered by bunks. Some companies use treated wood but because of the modern copper sulfate method of treating lumber, most manufacturers now use raw 2” x 4”s. You’d think treated would be better (won’t rot, etc). But the copper sulfate solution can bleed out of the wood. It will come through the carpet and discolor pontoon tubes. Warping is a problem with treated lumber and that’s why some trailer manufacturers use shorter boards. Not rotting is a feature but untreated wood will last 6-8 years or longer before it rots and by then you’ll need new carpet anyway. Warping can begin on treated bunks within months. A couple manufacturers use 2” x 6” bunks but unless you have 27” or larger pontoon tubes, there is no more surface supporting the pontoon tube. DEALERS NOTE: there is an application where 2” x 6” bunk is a benefit. Dealers, camp grounds, organizations, etc. handling pontoons with various size diameter pontoon tubes on a bunk style trailer, may want 2” x 6” bunks. Most pontoon boats have 72” to 77” centers. If you’re using a bunk style pontoon trailer to haul pontoons with different size tubes or various deck width’s, 2” x 6” bunks set at about 74” will allow you to haul most pontoon boats (72” to 77” centers) without adjusting the bunks for the different size pontoon boats. |

|||||

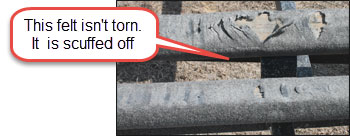

Carpet is generally used to cover the wooden bunks. There is a cheap way to cover the bunk and a better, longer lasting way. Common trailer bunk carpet is 10-12 ounce “felt” style carpeting. It’s thin and easy to work with and ideal for fishing boat or PWC trailer bunks. It forms and staples easily around the wooden bunk. However a heavier modern pontoon boat sliding 10’ on the felt stuff will shred it in a short time. Quality pontoon trailer manufacturers use 14 ounce rubber back marine grade carpeting. |

|||||

| Smart companies glue it to the wooden bunk and that helps keep it in place when your pontoon is rubbing across the surface. In the big scheme of things good carpet only adds about $20 to the cost of the trailer, but the same companies that don’t use it also use cheap tires and incandescent lights. The $200 you saved on the trailer you’ll spend for new bunk carpet, tires and lights. | |||||

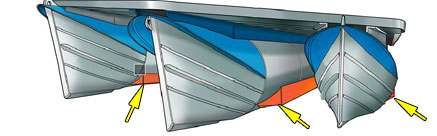

Some pontoons seem to tear carpet up more than others. This Avalon-Tahoe pontoon tube has sharp edges right where the tube meets the carpeted bunk. Sharp edges like this will rip any type of bunk carpeting. |

|||||

Lifting strakes can tear up bunk carpet. Come on a little crooked when loading, the sharp edges will shred the carpet. Most trailer manufacturers won’t warranty damaged bunk carpet and you’re usually on your own when your boat tears it up. |

|||||

|

Some manufacturers have

experimented with solid

plastic bunks but there are

difficulties. The cost of a

20’ plastic bunk is about

$40 more per bunk than a

carpeted 2” x 4”. Four bunks

at $40 each is $160, and

considered too much of an

upgrade by many. There are

strength issues with plastic

versus wood. Wood can be

more forgiving than plastic.

Where the bunk brackets

aren’t evenly spaced the

plastic bunks can sag from

the weight of a pontoon boat

on the trailer. Wooden

bunk’s seem to be the best

way to support pontoons. In 2012 a couple of companies developed bunk “slide sticks”. Usually 4’ to 6’ long, these pieces of plastic are applied over trailer bunks. They not only protect the carpet, they also allow the boat to slide on and off the trailer much easier. The sliding is a big benefit on shallow launching ramps. The problem with the 4’ to 6’ slide sticks is that for a pontoon boat you need multiple sticks and you must butt them together. Slide sticks can be expensive, costing almost as much as plastic bunk. |

|||||

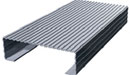

In

2013, a company developed

plastic glides that

manufacturers can buy in

1500’ rolls. The pontoon

trailer manufacture cuts the

plastic to size, 16’, 20’

etc. and uses the plastic

instead of bunk carpet. In

the big scheme of things

after the labor savings of

applying carpet, the plastic

is just a little more

expensive than carpet. Many

of the large trailer

manufacturers will adopt

this method. The problem is

that it takes a major

financial commitment from

the pontoon trailer

manufacturer to purchase the

plastic in volume and some

small companies won’t be

able to handle the expense.

You’ll see this more in the

future and it’s a great

option. In

2013, a company developed

plastic glides that

manufacturers can buy in

1500’ rolls. The pontoon

trailer manufacture cuts the

plastic to size, 16’, 20’

etc. and uses the plastic

instead of bunk carpet. In

the big scheme of things

after the labor savings of

applying carpet, the plastic

is just a little more

expensive than carpet. Many

of the large trailer

manufacturers will adopt

this method. The problem is

that it takes a major

financial commitment from

the pontoon trailer

manufacturer to purchase the

plastic in volume and some

small companies won’t be

able to handle the expense.

You’ll see this more in the

future and it’s a great

option. |

|||||

Here’s

an example of bunk wrap on

an expensive custom trailer.

Unfortunately the trailer

manufacturer bought the

plastic wrap as an

aftermarket “add on”. The

pieces of plastic are 6’ or

perhaps 8’ long and you have

seams along the length of

the bunks. What you want on

a new trailer is OEM grade

full length plastic covering

the length of the bunk. It

wouldn’t splinter or

deteriorate at the seams. Here’s

an example of bunk wrap on

an expensive custom trailer.

Unfortunately the trailer

manufacturer bought the

plastic wrap as an

aftermarket “add on”. The

pieces of plastic are 6’ or

perhaps 8’ long and you have

seams along the length of

the bunks. What you want on

a new trailer is OEM grade

full length plastic covering

the length of the bunk. It

wouldn’t splinter or

deteriorate at the seams. |

|||||

|

|

|

|||

| Felt bunk carpeting rubbed off. | Spray shields or lifting strakes cut this carpeting. | Plastic bunk wrap | |||

| HOME | 1 | 2 | | |||||

| PONTOON TRAILERS 101 - FOR EVERYTHING YOU NEED TO KNOW ABOUT PONTOON BOAT TRAILERS | |||||