HOME | 1 | 2 | |

|||||||

Pontoon Trailer: Axles, Hubs & Bearings |

|||||||

| AXLES | |||||||

The axle itself is nothing

but a piece of steel with a

spindle and mounting plate

welded to each end. Some

trailer manufacturers make

their own axles while others

find it simpler to purchase

them. Axle manufacturers

have worked to build brand

name recognition: Al-Co,

Dexter, Reliable etc. There

may be some slight benefit

of one brand over another.

The quality story, if there

is one, lies in the bearings

and the hubs. Hubs are rated

by their carrying capacity

and have to meet certain

Department of Transportation

requirements for the rating.

Thus an axle with “cheap”

imported hubs and bearings

(and most of them used today

are imported) will do what

it’s supposed to do. You’ll

seldom hear a pontoon

trailer manufacturer touting

the quality of their axles.

There really just isn’t much

to claim, except the

carrying capacity.  |

|||||||

Axles are vendor items for most trailer manufactures. Axle builders usually just spray paint the axles. They get scratched in transit and assembly. They seldom get touched up. Some companies claim they’re beneath the trailer, no one will notice. But many boats are off the trailer, often six months a year, when the axles rust, you will notice. Custom builders and higher quality companies use Aluminized axles. An aluminized coating helps prevent corrosion. It’s just cosmetic and isn’t much more expensive, but it’s a clue to the quality of the trailer your buying. |

|||||||

|

|||||||

|

|||||||

Spring axles are mounted with U bolt, these are called hanger brackets. There is no wrong or right way to mount them. I prefer when the bracket and nuts are on top. Many trailers are assembled on site, at a dealer or distributor, rather than at the manufacturer. It’s an extra safety precaution to be able to see that the nuts are on tight. The image to the left is Aluminized, nuts on top. The image to the right is painted with nuts on the bottom. |

|||||||

| Adjustable Axles | |||||||

Some large national

trailer manufacturers

use adjustable axles.

It’s a feature that is

usually not advertised

because adjustable axles

have gotten some bad

publicity. The benefit

is to the manufacturer.

They can stack more

trailers for shipping if

the distributor or

dealer puts the axles

on.

Bolting the axle is not generally a cost savings to the manufacturer. But it is a labor saving benefit in the manufacturing process. Attaching the axle to the frame is done by the distributor or dealer. This has given bolt on axles a bad reputation. |

|||||||

People assembling trailers in distributors or dealerships are generally not master mechanics, more often they are low paid “yard boys”. The chances of getting an axle on crooked or misaligned can be great. Even just off an inch will make the trailer “dog track” and wear the tires. Another problem is if the bolts aren’t on absolutely tight, a extreme shock (such as a pot hole) can loosen the bolts. |

|||||||

| Spring Axle Assemblies | |||||||

| The majority of pontoon trailer manufacturers use spring axle assemblies. | |||||||

|

|||||||

| Springs, like axles, are almost generic. When properly matched they carry your pontoon smoothly on good roads and help take the bounce out of rough ones. The axle assembly derives it’s capacity from the rating of the hub and the number of leaf springs. Fishing boat trailers may have only two springs. Most pontoon trailers will have four and heavy duty trailers may have five springs. Most trailer manufacturers simply state that the axle has a capacity of 2000, 2700, or 3500 lb. It’s usually stamped somewhere on the axle. The trailer owner should be aware of the carrying capacity. A axle with a 2700 lb. carrying capacity matched with a trailer that weighs about 600 lb. means the pontoon trailer can carry about 2100 lb. Most modern pontoon boats are over 2000 lbs. | |||||||

| The Weight Equalizer | |||||||

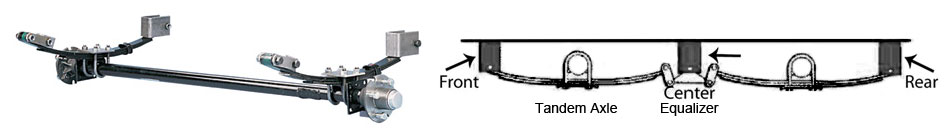

I

generally prefer spring

axles to torsion axles.

Especially for larger

heavier pontoons for one

simple feature. Spring axles

tied together in a tandem

axle system have the weight

of the load (boat) equalized

by a “rocker” in the middle.

It helps distribute the

weight of the boat between

the front and back axles,

equalizing the load. It is a

big benefit on bad roads. If

the front wheel goes down in

a pot hole, the equalizer

raises the back wheel so as

to prevent it from falling

quite as deep in the hole.

Helping it to “walk” over

the hole. You’ll feel the

jarring effect of the front

wheel but the back wheel

won’t hit quite as hard. I

generally prefer spring

axles to torsion axles.

Especially for larger

heavier pontoons for one

simple feature. Spring axles

tied together in a tandem

axle system have the weight

of the load (boat) equalized

by a “rocker” in the middle.

It helps distribute the

weight of the boat between

the front and back axles,

equalizing the load. It is a

big benefit on bad roads. If

the front wheel goes down in

a pot hole, the equalizer

raises the back wheel so as

to prevent it from falling

quite as deep in the hole.

Helping it to “walk” over

the hole. You’ll feel the

jarring effect of the front

wheel but the back wheel

won’t hit quite as hard. |

|||||||

| Torsion Axles | |||||||

|

|||||||

|

An alternative to spring

axles is the sealed rubber

torsion axle system. Springs

are replaced by rubber cords

inside the axle. The rubber

cords are compressed by the

“torsion” or twisting of the

axle inside. One of the

advantages of the torsion

axle system is that it is

very simple to mount. It’s a

benefit to the trailer

manufacturer and

distributor/dealer. They can

ship more trailers on a

stack. The

distributor/dealer can more

easily mount a torsion axle

than a spring axle. Usually

just four bolts. Generally

speaking torsion axles are

slightly more expensive, but

if you are shipping trailers

cross country, there is

freight savings with the

more trailers you can stack. I sold a line of trailers that used torsion axles for years. The claimed benefit was that they offered a smoother ride. When I was approached by another manufacturer I told them of my preference for torsion axles. Through actual towing demonstrations I was shocked to realize that I could not feel any difference. In fact, the spring axle handled a rough road better than the torsion axle. You can search the internet for the pros and cons and there may be some benefit towing with a smaller tow vehicle, but for modern pontoon boats I recommend and prefer the spring axle. |

|||||||

| HOME | 1 | 2 | | |||||||

| PONTOON TRAILERS 101 - FOR EVERYTHING YOU NEED TO KNOW ABOUT PONTOON BOAT TRAILERS | |||||||